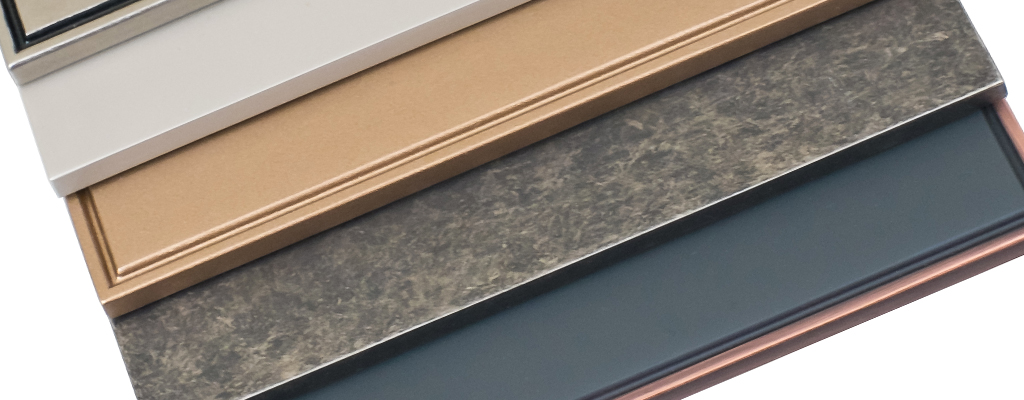

Antique Finishes

Midland Polishing and Plating have developed an Antique Finishes range comprising, aged brass, oil rubbed brass, burnished pewter and dark pewter.

These Antique Finishes are all achieved by immersing the component in a selenium based antiquing solution. The exact make-up of the solution differs slightly depending on what material is being oxidised. Other contributing factors are time, temperature and concentration of the solution.

Additionally, we have an antique gold finish which is an electroplating finish.

In some cases metal polishing or vibro polishing is required to obtain an authentic look.

The oxidised coating can also be relieved by a sateen mop to replicate an aged appearance.

An electrophoretic lacquer or wax can be applied to protect the coating from tarnishing and aid wear resistance, it also adds an attractive sheen.

The process can be used on various metals such as steel, zinc, brass and as part of the aluminium finishing.

All metals react differently, iron and steel will oxidise to a red rust or go black, zinc and aluminium will change to a white powder and silver will turn black. Copper and brass are best for antiquing because there is a wide variation of blues, greens and bronzes.

Oxidising cannot be achieved on satin chrome or bright chrome because trivalent chrome and hexavalent chrome is an oxidised film and the oxidising process will not be successful, but satin nickel, bright nickel, copper or brass electroplating can be used.

The antique finishes are mainly for decorative purposes only and it is not advisable for external environments unless a heavy coating of lacquer is applied which can change the aesthetics.

If you would like to discuss your polishing and plating requirements, please call 01902 421174 or use the website contact form to get in touch. One of our technical sales team will call you back.